Hydrogen Series Part 3:

Hydrogen compression and transportation by transmission pipeline – What are the impacts of Hydrogen blending on the physical properties of hydrogen and natural gas?

Authors: Mahmood Moshfeghian, Kindra Snow-McGregor, Ron Frend, Brian Inglis and Karl Gerdes

Introduction

In continuation of Feb and Mar 2023 “Tips of the Month” (TOTM) [1, 2] and given the amount of investment and interest in hydrogen, we have decided to publish a series of TOTM to explore the opportunities, challenges, and potential solutions to hydrogen applications and uses; this is the third paper in the series. In this TOTM we will review the physical properties of hydrogen and natural gas, which are quite different from one another. These differences govern the hydraulics of pipeline transmission.

Our future tips will explore the possible end uses and benefits of hydrogen, thermodynamics of natural gas use versus hydrogen in industrial applications, safety considerations, transportation challenges and opportunities, storage, and end use capabilities. In addition, we will look at some cost comparisons, where possible of the different hydrogen production options. We hope you enjoy taking this journey with us. Our aim is to take a thermodynamically balanced non-biased view of possible applications, costs, and implications.

Pipeline Operating Conditions and Typical Pipeline Gas Properties

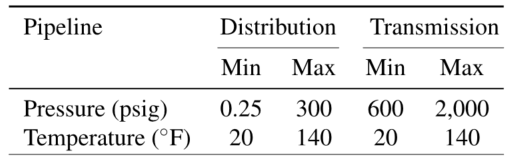

This section discusses the impact of blending hydrogen on natural gas properties and the need for accurate gas mixture property estimation for reliable model representations of the pipeline system. Table 1 (originally reported by Melania, Antonia, and Penev in 2013 [3]) provides a range of operating conditions. This table and the following ones are extracted from the 2022 NREL Report [2]

Table 1. Pipeline Operating Conditions (Melania, Antonia, and Penev in 2013 [3])

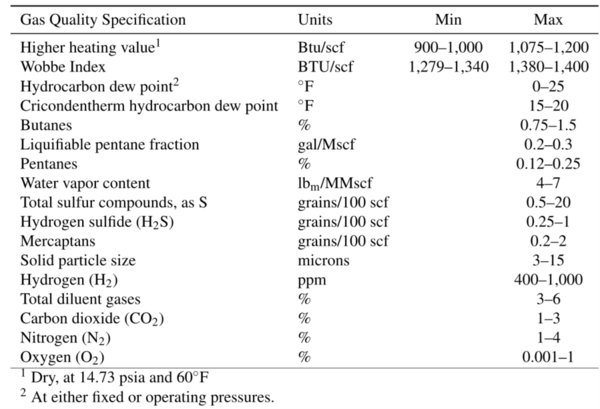

Table 2 (originally reported by the American Gas Association’s Gas Quality Management Manual (Grimley 2019 [2]) provides pipeline gas quality ranges that vary due to regional and provider-specific differences in natural gas pipeline transport specifications. The American Gas Association’s Gas Quality Management Manual and other studies provide a range of these operating conditions and gas qualities for both transmission and distribution pipeline systems. The pipeline gas quality specifications are largely driven around safety in transportation and end-use: water, and hydrocarbon liquids free at all anticipated pipeline operating conditions; heating value and Wobbe number ranges for stable combustion; minimized sulfur contaminants for controlled SOx emissions, etc... If the composition strays beyond the acceptable range, emissions may increase, and reliability of the end-use equipment may be reduced.

Table 2. Typical Pipeline Gas Properties (Grimley in 2019 [3])

Thermodynamics and Transport Properties

The variability in the composition of natural gas delivered in different regions across the United States is due to factors such as pipeline imports and local rich, and /or lean gas production from the regions oil and gas producers. To manage this variability, the interconnected pipeline system uses a combination of upstream gas processing facilities, pipeline tariffs (which outline the gas quality specifications), and operational flow orders. These mechanisms control the quality, composition, and transportation of gas to minimize the impacts of impurities and to balance system flows, and pressures to satisfy end-user demand whilst maintaining safe pipeline operating conditions. However, minor shifts in the gas composition will impact gas physical properties, such as density, dynamic viscosity, heat capacity, and others, which can result in operational challenges, capacity bottlenecks, metering inaccuracies, and degraded pipeline network control. To accurately estimate the effects of changes in gas composition on these properties, a variety of equations of state, such as Soave-Redlich-Kwong 1972, Peng-Robinson 1976, AGA8 DC92, and GERG-2008, are used in gas network modeling.

Combustion Properties

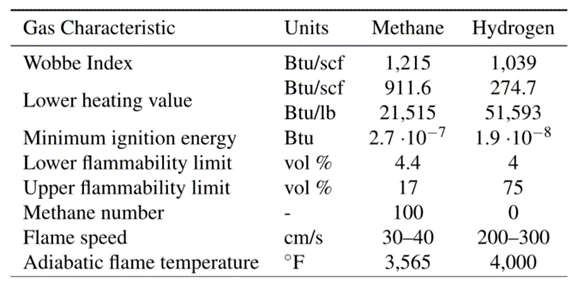

The combustion properties of hydrogen and natural gas are significantly different. Blending of hydrogen with natural gas changes not only the physical properties of the stream, such as density, dynamic viscosity, heat capacity and so on, but it also changes the heating value and Wobbe number. Table 4 (originally reported by (Kurz et al. 2019; Korb, Kawauchi, and Wachtmeister 2016; Goldmeer and Catillaz 2021 [4]) presents a high-level overview of combustion-related characteristics for hydrogen and methane (which is the primary constituent of natural gas) that can impact engines, turbines, and burners if significant quantities of hydrogen are present. These differences will also impact the pipeline compressor drivers (gas turbines or engines) if their fuel source is the pipeline gas.

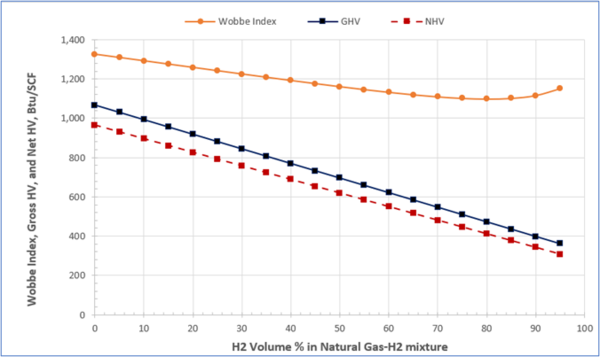

As the hydrogen content of natural gas increases, the mixture heating value decreases, reactivity, and combustion emissions changes occur. In addition, the mixtures become more unstable due to hydrogen's wider flammability window and lower minimum ignition energy. The Wobbe Index, which indicates fuel interchangeability, decreases until 85 vol % hydrogen and then increases, as shown in Figure 1.

Flames from pure hydrogen gas are nearly invisible and become more visible with the presence of impurities like methane. Flame speeds and temperatures rise as the hydrogen composition increases, potentially leading to increased nitrogen oxide (NOx) emissions from end-use device combustion. The limits for gas explosivity are case-dependent and require a more detailed analysis than the high-level overview provided in this section.

The following observations should be made regarding heating value, flame speed, flammability and minimum ignition energy required. Hydrogen’s lower heating value in Btu/scf is roughly 30% that of methane. As a result, blending hydrogen into pipeline transmission gas reduces the amount of BTU’s delivered per standard cubic foot of gas. This reduces the pipeline’s capacity to deliver the equivalent energy to end-users. The flame speed of hydrogen is roughly 7 times as fast as methane which will result in challenges for end-use devices such as gas engines and gas turbines. These devices would likely require design modifications to safely run on blends and pure hydrogen as a result. The flammability range of hydrogen is very wide (4 – 75 vol %), and it has a much lower minimum ignition energy required. Pipeline transmission of pure hydrogen or natural gas hydrogen blends increases the risk of fires or explosions that can result in the event of loss of containment.

Table 3. Methane and Hydrogen Combustion Properties [3]

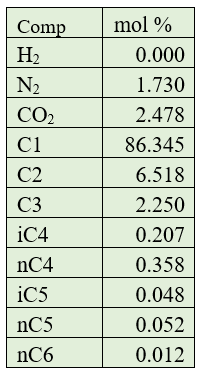

Table 4. Composition of natural gas mixed with hydrogen to generate Figure 1

by using ProMax [4]

Figure 1. Effect of hydrogen composition on Wobbe Index

Summary

For effective pipeline system modeling, precise gas mixture property estimation is crucial over the range of relevant operating conditions. Operating conditions and gas quality vary across regions and providers, which influences natural gas composition and affects the design and tuning of end-use equipment. Exceeding the acceptable composition range may increase emissions and reduce equipment reliability, or worse, may lead to end-use device failures.

The thermodynamic and transport properties of the delivered natural gas vary across different regions in the U.S. The current natural gas pipeline system manages this variability through upstream gas processing, pipeline tariffs, and operational flow orders. Small shifts in natural gas composition can cause operational challenges due to changes in gas mixture properties, potentially leading to capacity bottlenecks, metering inaccuracies, and degraded pipeline network control.

The physical properties, including combustion, of hydrogen differ from natural gas, which can cause complications for pipeline operations and end-user applications when blending hydrogen. These differences can impact pipeline compression station operations and may influence factors such as mixture heating values, reactivity, and emissions. Hydrogen mixtures tend to become more unstable as hydrogen content increases, and flame visibility, speed, and temperature also change with increasing hydrogen composition. The higher flammability range and lower minimum ignition energy required of hydrogen will increase the level of hazard associated with any pipeline loss of containment event.

References:

- Snow-McGregor, K., Frend, R., Inglis, B., Gerdes, K., “Hydrogen Series Part 1: Hydrogen Colors – What do they mean, Options for Production and their associated Challenges?”, PetroSkills Tip of the Month, Feb (2023)

- Snow-McGregor, K., Moshfeghian, M, Frend, R., Inglis, B., Gerdes, K., “Hydrogen Series Part 2: Hydrogen compression and transportation by transmission pipeline – What are permissible conditions and limitations and their associated challenges?”, PetroSkills Tip of the Month, Mar (2023)

- NREL, Hydrogen Blending into Natural Gas Pipeline Infrastructure: Review of the State of Technology at https://www.nrel.gov/docs/fy23osti/81704.pdf ,Oct (2022)

- ProMax 6.0, Bryan Research and Engineering, Inc., Bryan, Texas, (2023)