Part 1 – A Basic Review of the APCI C3/SMR World LNG Positioning and Impact

The birth of modern day LNG production and worldwide commerce commenced with the 1958 conversion of the NORGULF’S Shipping Line’s freighter, NORMANTI into the newly designed world’s first LNG carrier renamed the Methane Pioneer. The vessel was fabricated by the recently formed Constock International Methane (CIM) consortium. The Methane Pioneer was retrofitted for LNG transport, and designed to carry 5 000 m3 (32,000 Bbls) of LNG, equivalent to some 2,375 tonnes of LNG, corresponding to 3.23 x 106 std m3/114 MMSCF of liquefied process gas. Her maiden voyage was from Constock’s LNG production facility on the Calcasieu River in Louisiana on 25 January 1959 to its destination at Canvey Island in England, arriving on 20 February.

Since that time, the worldwide LNG Export/Import evolution has risen from an initial 10-50 million tonnes per annum (mtpa) during the 1970 – 1990 era to a world Energy demand for LNG by 2018 of some 431 billion cubic meters – std. ( 15.2 trillion cubic feet – std.) equivalent to some 319 mtpa.

To date there are many Liquefaction Technologies available for LNG processing, that are part of the Exploration/Transportation/Liquefaction/Worldwide LNG Value Chain. This Tip of the Month will provide some current information regarding one of the most commonly applied LNG liquefaction technologies known as the APCI Propane Pre-cooled (C3) / Single Mixed Refrigerant (SMR) process which is present in over 40% of the worlds’ 33 existing LNG Plants as of 2018.

The existing APCI C3/SMR liquefaction process has been proven to be very energy efficient, thermodynamically stable, operator friendly, operationally reliable, and applies well known refrigerant components for the process. The Tip seeks to provide a current day insight into the intrinsic operation of a typical 500 MMSCFD (14.2 x 106 std m3/d) process gas, (10,000 t/d; 3.65 mtpa) LNG APCI liquefaction facility applying a Single Mixed Refrigerant, sometimes denoted as SMR or frequently shortened to MR. In some specific installations worldwide, plant operators prefer the SMR reference.

A review of a typical inlet process gas, along with in plant LNG gas properties will be provided. The Propane Cycle operation in terms of mass, and energy flow for four (4) liquefaction stages of cooling of the Process Gas and MR is also discussed. Thermodynamic conditions for the APCI Main Cryogenic Heat Exchanger (MCHE) LNG liquefaction is presented. The intricate nature of the combined C3/MR process will be reviewed in detail to yield an insight into the thermodynamic stability, and consequential reliability of the process that justifies its vast process application throughout the world.

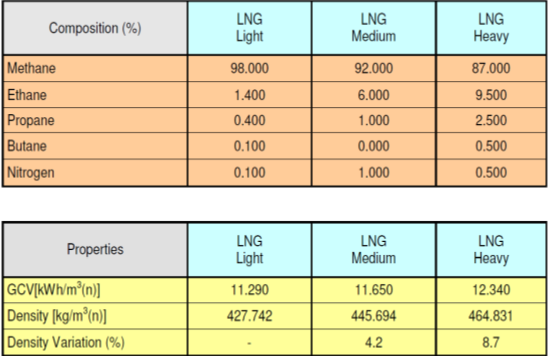

Table 1 [1] reviews the typical compositional ranges for an LNG Process Gas expressed as: LIGHT, MEDIUM, and HEAVY. Notice that important parameters such as the GCV (Gross Calorific Value) given in units of kWhr/m3(n). Convenient conversions may be adapted recalling that a kWhr corresponds to 3600 kJ (3429 BTU), and 1 kcal = 4.184 kJ. Additionally, typical LNG densities are given.

Table 1. Typical LNG Compositions, GCV, and Cryogenic LNG Densities. [1]

As shown by Table 1 [1], there is a reasonable range for acceptable LNG Process gas compositions. The APCI C3/MR cryogenic process is very sensitive to the inlet gas composition. In addition, the integral sections of “pre-processing” or “gas conditioning” processes prior to condensation such as: gas sweetening, pre-cooling, dehydration, and mercury removal are sensitive to the inlet gas composition and the required quantities of contaminants that need to be removed. Notice, the LNG densities that are provided for the various compositions reflect the overall “condensation ratios” in std m3/tonne (scf/tonne). These variations will have an important impact on the performance of the MCHE, selection of the MR composition, and mass flow ratio of the MR to LNG Process Gas. These issues will be addressed in detail in Part 2 of this TOTM, when an actual CASE STUDY will be analyzed.

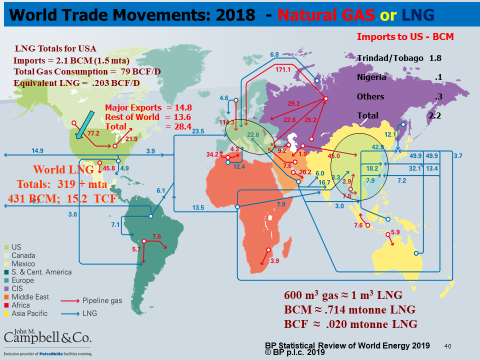

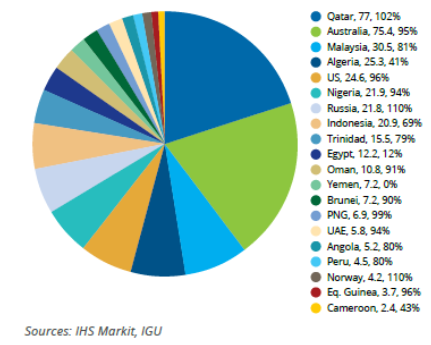

To begin the discussion, it is convenient to observe the 2018 Natural Gas and LNG worldwide trade movements during 2018 [2]. Figure 1 [2] indicates that some 431 BCM (15.2 tcf), equivalent to 319 mta of LNG taken at an applicable conversion of 1360 std m3/tonne (48,000 scf/tonne) were commercialized. These imports emanated from 20 principal exporters indicated in Figure 2 [3].

This Figure indicates a total “Nominal Worldwide Capacity” of 383 mtpa, of which some 83% were actually exported.

Figure 1. Major Worldwide Natural Gas and LNG Commerce during 2018 [1]

Figure 2. Major Worldwide LNG Exporting Countries during 2018 [3]

Note: Nominal Liquefaction Capacity in mtpa and % Utilization – Total 383 mtpa

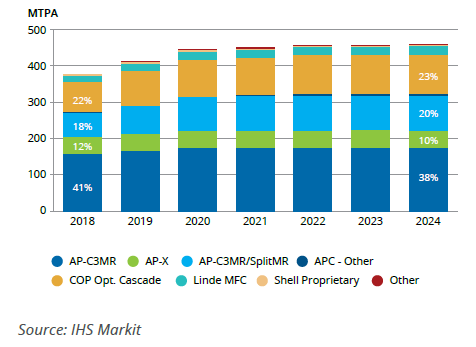

Figure 3 [3] shows the percentage application of the world’s major LNG liquefaction processes. Shown are the configurations of the APCI processes, as well as the most commonly applied other technologies. As can be observed, the APCI-C3MR process reflects some 41 % of all the worlds installed processes in 2018, and is clearly the most commonly applied liquefaction technology. Notice that APCI has four (4) processes that are active; however, not as highly utilized as the cited C3/MR. The AP-X process applies a Nitrogen Expander and HEX parallel refrigeration system that provides the final liquefaction, The AP-C3MR/Split MR applies two Turbines, with the refrigeration power equally split between the turbines. One compresses the propane refrigerant and the high pressure stage of the MR. The second is used for MR low, and medium stage compression. As the focus of the Tip is to track the basic APCI-C3MR process, the reader is referred to the LNG literature to find details on the other processes in operation.

Figure 3. Distribution of LNG Liquefaction Processes: 2018, 2019 and projected to 2024 [3]

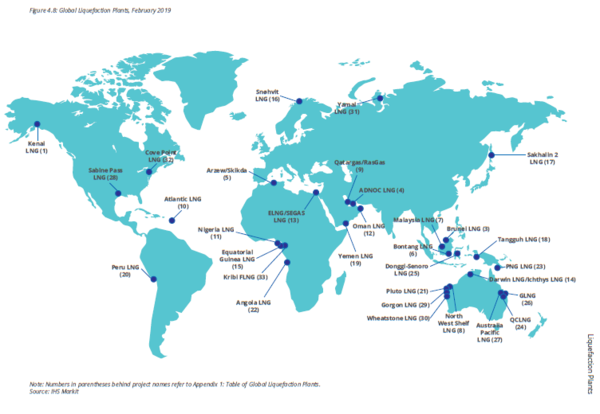

In terms of Globalization of the LNG Market Figure 4 [3] indicates the major LNG Liquefaction facilities throughout the world. Some USA Units are not shown due to late 2018, or early 2019 incursion into the Export Market. Missing are Cheniere Corpus Christie, Texas, and Sempra Cameron, Hackberry, La. Of these Facilities, Dominion Cove Point, Cheniere Sabine Pass, and Trans-Foreland Kenai are Optimized COP installations, while the remaining two (2) are APCI C3MR.

Figure 4. Worldwide Major Liquefaction Facilities. 2018 [3]

Note: refer to text for missing USA Export Units not shown

An Introduction to the APCI C3/MR Process

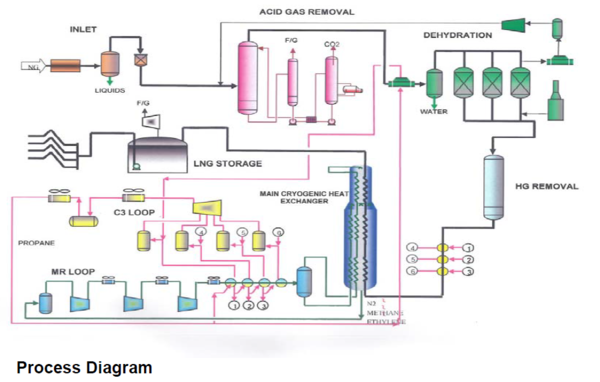

As shown by Figure 5, the typical Process Flow Diagram (PFD) for an operating APCI C3/MR LNG Plant consists of various integral components:

1) Inlet Separation: Usually in range of 7-8 MPa; [1000-1160 psig] and to 20-30 °C [68 – 86 ºF].

2) Inlet Process Gas Sweetening: removal of CO2/H2S and mercaptans to nil levels.

3) Process Gas Pre-Cooling prior to Dehydration: Usually at pressure and cooled to 15-18 °C [60 to 64 ºF].

4) Process Gas Molecular Sieve Dehydration: water dewpoint temperature to -162 ºC [-260 ºF] at MCHE pressure levels

5) Mercury Removal: LNG Plant levels to 0.01 μg/Nm3, or 0.01 ppt by volume.

6) Not shown in this APCI C3/MR Plant PFD are facilities that handle condensed C4/C5 + components that are directed to In-Plant Fractionation, where heavy liquids are separated and used for MR make-up, possible inlet stream reinjection and/or NGL product sales.

7) The MR is compressed from the MCHE discharge in a low temperature, low pressure superheated phase in range of – 46 to – 50 °C, [-51 to – 58 ºF], and typically 400 – 600 kPaa [ ~ 60 – 90 psia]. Subsequent compression is typically in three (3) stages takes the MR to its final pressure. The MR is cooled by four (4) stages of Propane chilling, and enters the MCHE as two (2) phases usually at 50 – 70 bar, 5 – 7 MPa; [725 – 1000 psig] and -32 to -38 °C [-26 to -36 ºF]. The separated vapor, LMR (light mixed refrigerant) and liquid, HMR, (Heavy Mixed Refrigerant) stream enters the MCHE at the bottom. The process gas is commonly cooled also in four (4) stages prior to entering MCHE inlet separator at temperatures also in range of -32 to – 38 °C [-26 to -36 ºF]. The MR is discharged as a superheated gas generally at low pressure, some 350 – 600 kPaa [51 – 90 psia], and temperature below the entering LNG gas temperature, in range of – 46 to – 50 °C, [-51 to – 58 ºF].

8) The MCHE operates at the cited inlet temperatures, and pressures usually in range of 50 – 70 bar, 5 – 7 MPa [725 – 1000 psig]. The outlet of the MCHE operates at pressures and temperatures in range of 50 – 60 bar, 5 – 6 MPa [725 – 870 psig], and -162.5 to -163 °C [-260.5 to -261.4 ºF].

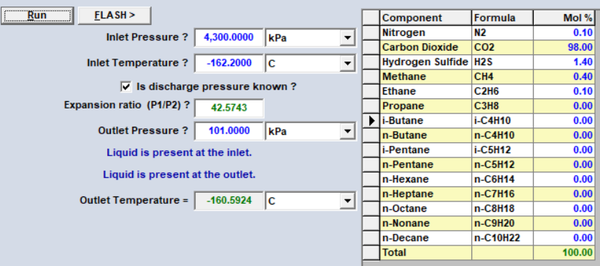

9) The final ISENTHALPIC expansion of the Liquefied LNG to 101 kPaa (14.7 psia) may actually undergo a slight “HEATING” of some 0.5 °C [~ 1 ºF]. The Joule-Thomson (J-T) coefficient can either be positive or negative. For most gases, the J-T coefficient is positive, i.e. the gas cools upon expansion. However, for most liquids and high-pressure hydrocarbon gases at low temperatures, the J-T coefficient is negative, i.e., the fluids warm upon expansion. For the APCI C3/MR process, the final expansion of the LNG typically occurs high pressure, resulting in the final LNG product at -162 °C and 101 kPaa [-260 °F and 14.7 psia].

Figure 5: Process Flow Diagram – Example PFD APCI LNG Processing Plant

A Brief Insight into typical LNG and MR Compositions and Phase Envelopes

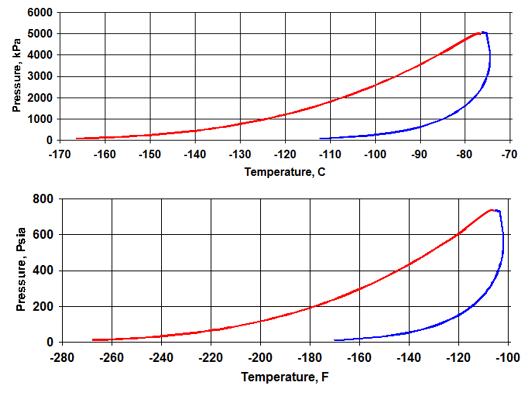

With the intention to provide some insight into the actual appearance of the phase envelopes of the mentioned LNG streams, as well as a typical MR stream [5], Table 2 [1/5], and Figure 6 [5] represent the composition and phase envelope of a LIGHT LNG (taken from Table 1). As can be seen the critical point for pressure/temperature are virtually coincident with the cricondenbar. This means that LNG MCHE liquefaction above 50 bar (5000 kPaa – 725 psia) will not result in an internal two phase LNG stream, but reflect a “dynamic” condensation criteria as the process stream is cryogenically cooled. As also may be observed, final “ISENTHALPIC” expansion to storage conditions theoretically yields a saturated LNG liquid at -162 °C and 101 kPaa [-260 °F and 14.7 psia].

Table 2 [1]. Composition for a Typical LIGHT LNG (from Table 1)

Figure 6. Phase Envelope for a Typical LIGHT LNG (from Table 1) [4]

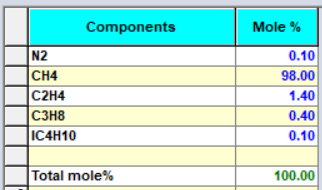

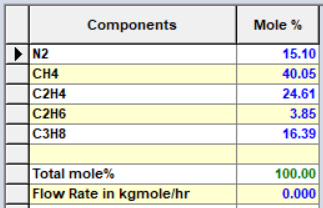

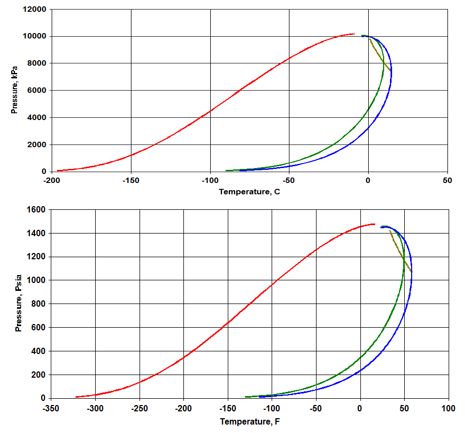

It is also interesting to observe some selected typical information for an MR applied to an APCI Process. Table 3 [5], and Figure 7 [4] represent the composition and phase envelope of a given MR from an independent source. The selected MR has a small amount of ethylene to yield ample volatility. As can be seen, once again the critical region for pressure/temperature values are virtually coincident with the Cricondenbar. Also clearly shown is the capacity of the MR for required compression, and cooling at the pressure and temperature levels cited in Point 7) above. It is of interest to note that the MR displays a very distinct two – phase system in the pressure/temperature regions mentioned in Point 7) as the two streams are fed to the MCHE. The green line in the Phase Envelope represents 90% Vapor Quality. The MR discharged from the MCHE after absorbing the HEAT LOAD from the LNG process stream is seen to be a superheated vapor at low temperatures and pressures in range of – 46 to – 50 °C, [-51 to – 58 ºF], and 350 – 600 kPaa [51 – 90 psia].

Table 3. Composition for a Typical MEDIUM Molecular Weight MR [5]

Figure 7: Phase Envelopes for a Typical MEDIUM Molecular Weight MR [4]

It is obviously not the intent of the present TOTM to describe all LNG Plant Process Components. The purpose is to review the operation of the MCHE and its integral components and feed streams. These will include the review of the Propane Cycle mass flow, pressure and temperature levels, heat loads, and total compression power required to cool of the Process Gas plus the MR to requirements for entry into the MCHE and subsequent LNG liquefaction and production to the Storage Facility.

The Sequence of Numerical Calculations Required to Quantify the APCI C3/MR Process

Referring to the previous section, a specific Nine (9) items of analysis must be addressed in an interrelated fashion in order to quantify the performance of an APCI C3/MR LNG Process Plant.

Points 7), 8), and 9) are the essential analyses that must be addressed after the inlet feed gas has been pre-conditioned (sweetened, dehydrated, and liberated from mercury). This sequence will be detailed in this section before entering into an actual case study. It will be assumed that the processing of the inlet gas as per Points 1) through 6) has been performed; however, mention will be made so as to provide continuity of the Plant operations. In order to analyze any given APCI installation downstream of all previous plant processes, and before both the LNG Process Gas, and MR enter the MCHE, the following numerical analyses need to be addressed:

A) APCI C3/MR operations related to the LNG sweetened, dehydrated, and mercury free LNG Process Gas:

► It is assumed that all plant feed gas processing and treating upstream of the MCHE have been performed. These all require knowledge of inlet composition, volumetric and mass flows along with pressures, and temperatures pertaining to the upstream systems cited in Points 1) – 6). The inlet gas is sweetened, treated for removal of heavy components, dehydrated, and then treated for mercury removal. It should be noted in some facilities, the mercury removal unit maybe in the front of the plant prior to sweetening, but is a less common process configuration.

► The LNG process gas should be defined in units related to both MMscfd (106 std m3/d) as well as in total mass flow in tonnes/d. The inlet temperature and pressure are defined as well. It should be noted with reference to Figure 5, the first Propane Chiller operating at the highest pressure and temperature cooling level is usually placed upstream of the molecular sieve dehydration unit to minimize the required size and operating costs of the gas dehydration unit. Pre-cooling the incoming wet feed gas condenses out a portion of the saturated water content where it can be removed upstream of the dehydration unit Point 4).

► With knowledge of the final composition of the LNG process gas, an Energy Balance must be performed for the mass flow entering and leaving the MCHE at the inlet/discharge ranges of pressures and temperatures cited. It should be remembered that the LNG process gas presents a superheated phase at inlet conditions, then is condensed into a two-phase region if the LNG phase diagram shows an operating pressure and temperature within this phase region. If the MCHE operating pressure is greater than the process gas Chricondenbar, the LNG will undergo dynamic condensation to a sub-cooled liquid within the MCHE discharge at the top of the Exchanger.

A) APCI C3/MR operations related to the LNG sweetened, dehydrated, and mercury free LNG Process Gas: Cont’d

At this point the LNG is at a high pressure, and cryogenic temperature as cited in Point 8). Recall that isenthalpic expansion of the sub-cooled LNG will probably yield a slight temperature increase, as per Point 8).

When prepared for storage, the cryogenic LNG product will be at near atmospheric pressure, and temperatures very close to -162 C [-260 F]. Figure (8) shows the results for this expansion for the LNG at a typical MCHE conditions. At this resting point the LNG is theoretically a saturated liquid at its atmospheric bubble point. The energy balance is generally expressed in MW (KWx1000). This final cryogenic condensation presents a good opportunity to validate the gas to LNG condensation ratio in scf/tonne (std m3/tonne). The normal ranges for the process is a direct function of the process gas composition (Molecular Weight, and LNG Relative Density); however values usually tend to be in the range of 1,300 – 1,360 std m3/tonne [46,000 – 48,000 approx. scf/tonne].

Figure 8: Isenthalpic Expansion of Light LNG, shown in Figures (6), indicating a slight temperature Increase when expanded for 43 bar to 1 bar at indications shown [4]

► An essential aspect relating to the APCI C3/MR process dynamics is to determine the MR to LNG process gas mass ratio. This procedure is performed after an Energy Balance is performed on the LNG process gas entering, and exiting the MCHE as cited in Point 8). There are various options that may be selected in choosing the components and their compositions in the MR, but a few essential conditions must be met: 1) As stipulated in Point 7) the MR is compressed typically in three (3) stages; 2) The MR enters the MCHE in the two-phase region as Liquid/Vapor and is discharged in the superheated vapor region as cited in Point 7); 3) Once the MR composition has been determined, the total mass flow required will be fixed by the Energy Balance of the LNG, yielding the energy to be extracted from the LNG process stream equal to the energy absorbed by the MR. It has been shown by many applicable studies that this Flowing Mass Ratio: Mass MR/ Mass LNG Process Gas is in the range of 2.2 – 2.6.

The units are usually expressed in tonnes/hr. As an arbitrary example, an LNG gas stream of 10,000 tonnes/d [417 tonnes/hr] will require an MR of some 22,000 – 26,000 tonnes/d [917 – 1084 tonne/hr]. The MR composition is essential to the thermal efficiency of the process, and will be discussed further in Part 2.

In Part 2 of this Tip of The Month, a particular CASE STUDY will be introduced and analyzed. An appropriate LNG composition will be presented, along with a representative gas flow rate in MMscfd [106 std m3 /d]. Typical pressures, temperatures, for the LNG gas and MR will be applied. An applicable MR composition will be assumed, that will incorporate the necessary behavior to satisfy its essential phase behavior points discussed in this Part 1 of the TOTM. With the known LNG gas mass flow rate, and calculated MCHE cooling duty as per guidelines of this Part 1 of the TOTM, the known MR composition will yield its required mass flow rate. To determine the required Propane refrigerant cooling duties for the process LNG, and MR, five (5) propane pressure, and temperature levels will be employed between near atmospheric pressure to final refrigerant discharge pressure. This design will provide for four (4) stages of propane compression and cooling for both the process gas LNG, and MR. Compression levels for the MR Turbo-Compressors will be taken in accord with guidelines presented, allowing MR feed to the MCHE as a two phase stream., and discharge as a low pressure single phase gas. For the process gas LNG, guidelines of Part 1 of this TOTM will be followed for four (4) cooling levels in preparation for entry into the MCHE. The Total cooling duties for the MR and LNG Streams will be determined, along with total required propane refrigerant mass flow, and total stage duties.

To learn more about LNG, we suggest attending our G2 (Overview of Gas Processing), G29 LNG (Short Course : Technology and the LNG Chain), and G4 LNG (Gas Conditioning and Processing-LNG Emphasis) courses.

Written By: Dr. Frank E. Ashford & Kindra Snow-McGregor

References

1. Accurate determination of LNG quality unloaded in Receiving Terminals: An Innovative Approach: Angel Benito, Enagás, S.A.

2. Statistical Review of World Energy, 2019 BP.

3. IGU Annual Report 2019 (IHS MARKIT)

4. GCAP 9.3.2, “Gas Conditioning and Processing Computer Program,” Editor Moshfeghian, M, PetroSkills, Katy, Texas, 2019.

5. Typical SMR MEDIUM Composition for APCI Process: Private Communication