Written by Pete Luan

This article will address one of the key challenges in managing Brownfield Projects. That challenge is fully understanding the existing condition of the facility where our project will be installed. Failure to understand the existing site and facility conditions will have a dramatic, negative impact on the work scope. This is perhaps the biggest reason why Brownfield Projects tend to be much more challenging than Greenfield Projects. The article will address techniques that the project engineer can utilize to mitigate these surprises and ultimately manage scope changes.

In this article, you will learn about:

1. Greenfield vs Brownfield project challenges

2. How to overcome the biggest Brownfield project challenge using Due Diligence

GREENFIELD VS BROWNFIELD PROJECT CHALLENGES

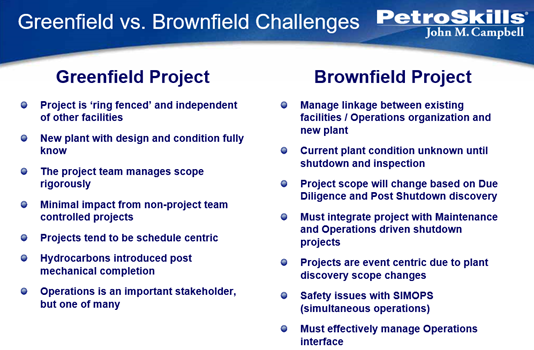

The first item we need to establish is what is the difference between a greenfield and brownfield project. This graphic below summarizes the main challenges for each type of project.

Figure 1. Comparison of Greenfield and Brownfield Challenges

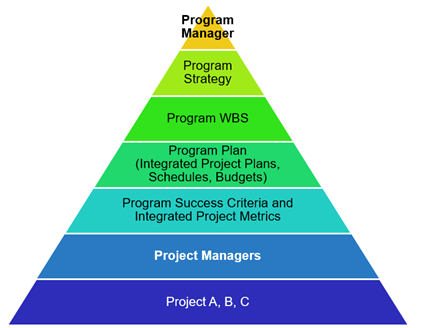

As a project proceeds, it is important to know where the Brownfield Project stands in the hierarchy with respect to an operations-centric shutdown or turnaround. Brownfield projects are integrated with operations work plans which means a project manager must be aware how their plans affect operations and business objectives. Figure 2 gives an example of a typical brownfield project hierarchy. Some key points to understand are:

- The program manager is often an operations individual

- Program strategy, program WBS, and the program plan are typically driven by operations and maintenance departments

- Business objectives are driven by operations

- The brownfield project plan must integrate with the overall operations program

- Operations has priority and often drives the shutdown or turnaround

Figure 2. Example of brownfield project hierarchy with respect to a turnaround or shutdown

Brownfield Project Challenges

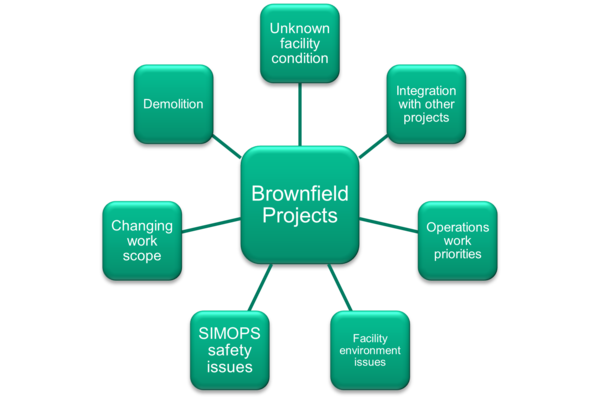

When it comes to brownfield project challenges, you’ll never be able to eliminate surprises, but you can minimize them. Figure 3 lists the typical challenges you will confront during a brownfield project.

Figure 3. Brownfield Project Challenges

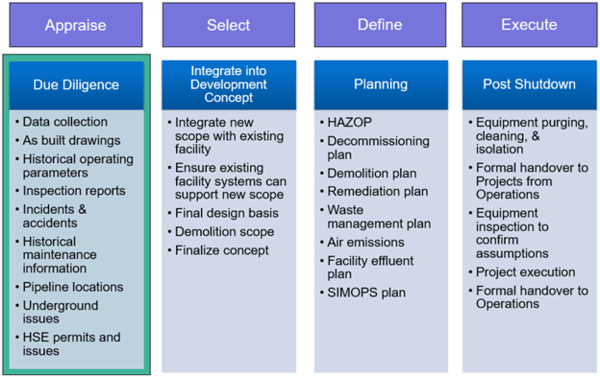

To have any chance of success for a Brownfield Project there are a whole series of things that need to be done on “top” of a typical stage-gate process. This occurs because there is an established facility and you must integrate your work scope with that existing facility. A greenfield project is much simpler as often one builds a new facility without all of the entanglements, interfaces, and complications of an existing plant. So, what we are showing you in Figure 4 is what we believe to be the key to success during the Appraise Stage and that is doing your due diligence. This is the core to the entire brownfield project because if you don’t get this right, you will be susceptible to a lot of surprises. All of the due diligence items illustrated below go above and beyond the typical stage-gate process. That is why this process is effective and mitigates scope surprises. Due Diligence during the Appraise Stage is critical to fully understanding the work scope including ‘hidden’ items.

Due Diligence is but one of a series of extra steps that the project manager must incorporate into their stage gate process to ensure the project is properly planned. Requisite activities for the other stages are illustrated in the figure below.

Figure 4. Due Diligence and the Appraise Stage

DUE DILIGENCE IN ACTION

Recall that we do due diligence so that the site and facility conditions are thoroughly understood prior to moving to the field during a shutdown or turnaround. One does not want surprises during a turnaround and this process will help mitigate potential surprises.

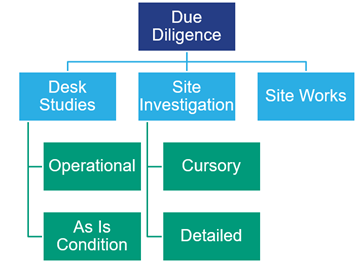

There are three major categories of due diligence. They include desk studies, site investigation and site works. If you look at the progression in Figure 5 it represents the order in which each due diligence activity should take place. Desk studies should be completed at the office and can be time consuming but are critical. Site investigation is used to confirm all the desk studies, and if there is information you cannot retrieve from site investigation you typically need to do site works. Site works can involve excavation, detailed laser surveys, smart pig utilization, insulation removal, etc.

Figure 5. Three major categories of due diligence

Another way to show this can be seen in Figure 6. For better understanding, desk studies and site investigation can be broken down into two categories. The idea is to make due diligence easier to understand which helps us assign resources to each of these tasks.

Figure 6. Three major categories of due diligence including sub-categories

Desk Studies

Operational: Let’s discuss due diligence on an operational level. In your office, you first want to get access to the plant operating data, historical operating parameters, materials processed at the facility, past operational events, etc. Additionally, you want access to incidents and accidents history as well as historical maintenance records.

Each of these sources of information educates you on the operational history and issues for which you should already be aware. When looking at the maintenance history, for example, you will see information on how the unit has been maintained and this will give you an idea what you will find when you initiate project construction work.

As Is Condition: This section of due diligence includes the plant layout and accessibility, as built drawings, and equipment/line inspection reports. Plant history timeline is important as it includes revamps, modifications and shutdowns. You also need to be aware of potential underground obstructions, pipelines, HSE permits and associated issues.

The goal is to learn what to expect when you go out to visit the project. For example, are the drawings up to date? Is the work site easily accessible?

For a modest sized project consider utilizing an engineering contractor as Desk Studies can be very time consuming.

Site Investigation

Cursory: At this point we have done all the due diligence we need to at the office and now we are going out to the job site. On the job site, the goal is to confirm the information we found during the desk studies. Once there, you want to complete cursory process data gathering and confirm access to equipment. The best source of any kind of on-site information is existing operations and maintenance staff. I strongly recommend you spend time with them to answer any questions from your previous research and to confirm the potential condition of the facility. Lastly, complete a visual inspection of the facilities.

Detailed: Many of the sites you will be involved in are “legacy sites” or sites that been around awhile and as such, will not always have as built drawings. However, you should always try to confirm the validity of the engineering drawings. Other potential activities include ultrasound testing for thickness or integrity measurement, underground surveys, and utilizing Smart Pigs and Point Cloud Laser Surveys. All of this is important data that will help the project engineer understand the existing condition of the facility.

Site Works

The last stage of due diligence is useful if you are unable to confirm the requisite information. When other measures have failed, excavation is a typical way to confirm underground obstructions. Partial demolition can also be used to investigate. It should be noted that this type of work is often intrusive to an operating unit, so it should be done only as a last resort.

In conclusion, now you should have a better understanding of the challenges associated with managing a Brownfield Project successfully and the starting point for implementing Due Diligence processes with your projects. The key takeaways from this article are as follows:

- You’ll never be able to eliminate surprises, but you can minimize them.

- As a project proceeds, it is important to know where you sit in the hierarchy with respect to a shutdown or turnaround. Brownfield projects are integrated with operations work plans which means a project manager must be aware how their plans affect operations and business objectives.

- The “biggest” Brownfield project challenge is minimizing surprises and fully understanding the existing condition of the facility where our project will be installed.

- The key to success during the Appraise Stage is doing your due diligence. It is critical to fully understanding the work scope including ‘hidden’ items.

To learn more about turnaround and brownfield projects, we recommend enrolling in an upcoming session of Managing Brownfield Projects – FPM42. Search the full project management schedule for more courses.