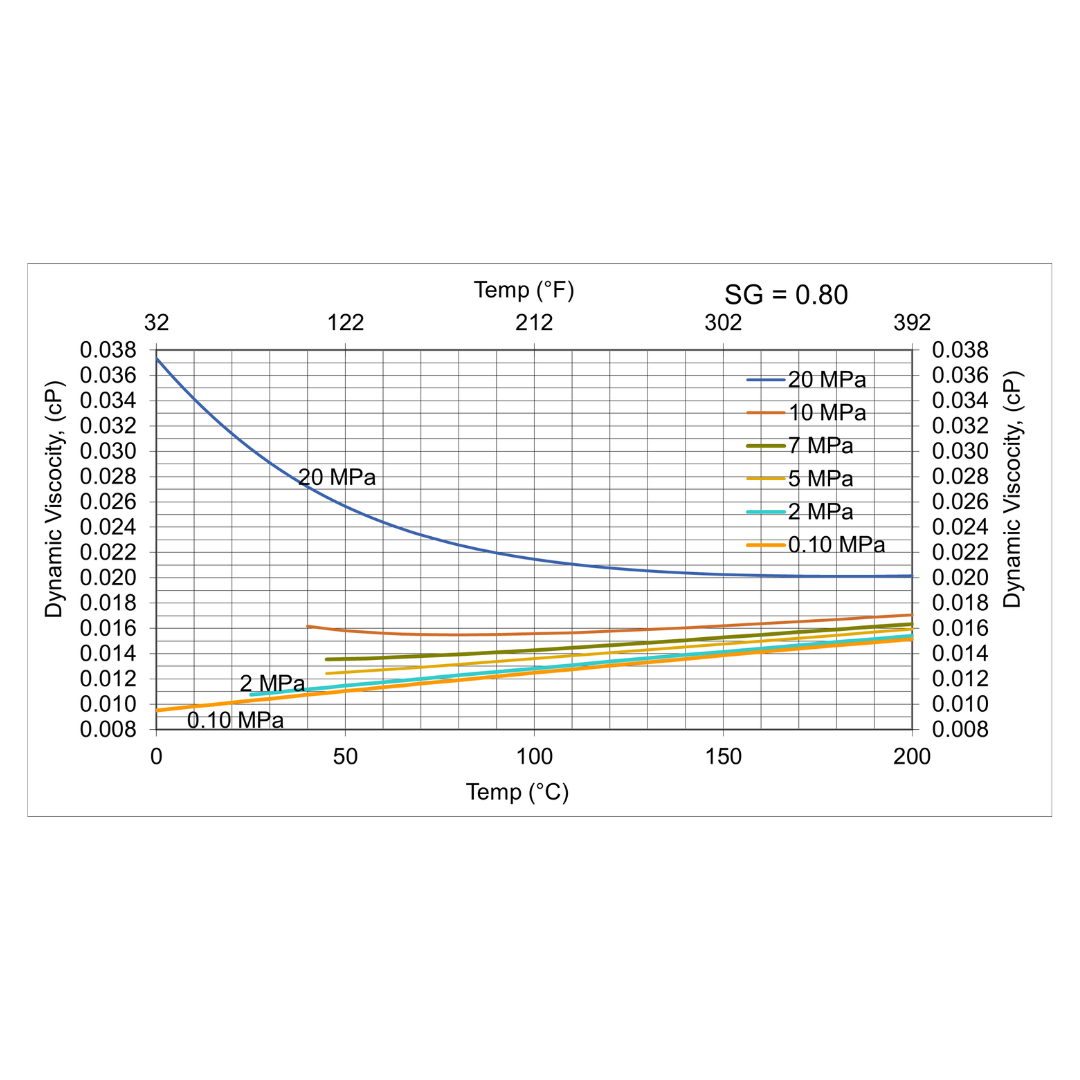

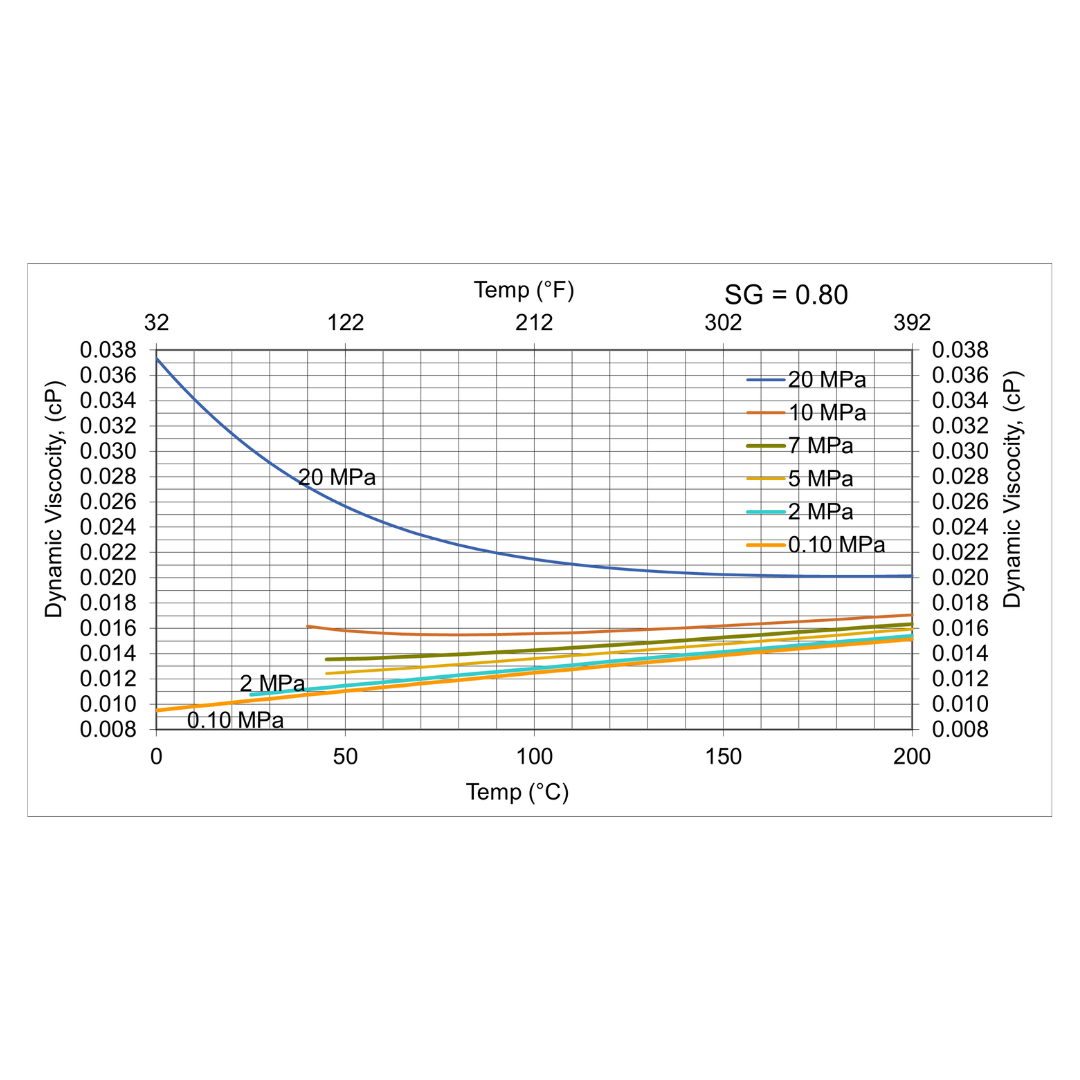

Variation of Natural Gas Viscosity with Temperature, Pressure, and Relative Density

December 20, 2022

|

Tip of the Month

In general, gas viscosity is used in fluid flow pressure drop calculations, detailed heat exchanger calculations, and droplet settling calculations for separation. It is also used for trouble shooting and equipment sizing.

In this Tip of The Month (TOTM), several options/methods for estimating viscosity of lean sweet natural (hydrocarbon) gases as ...

View Article

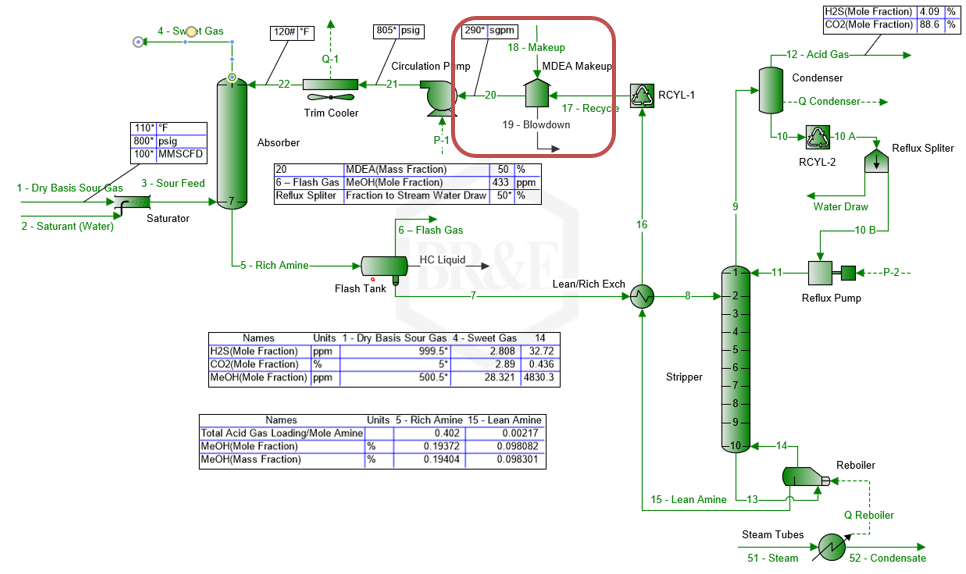

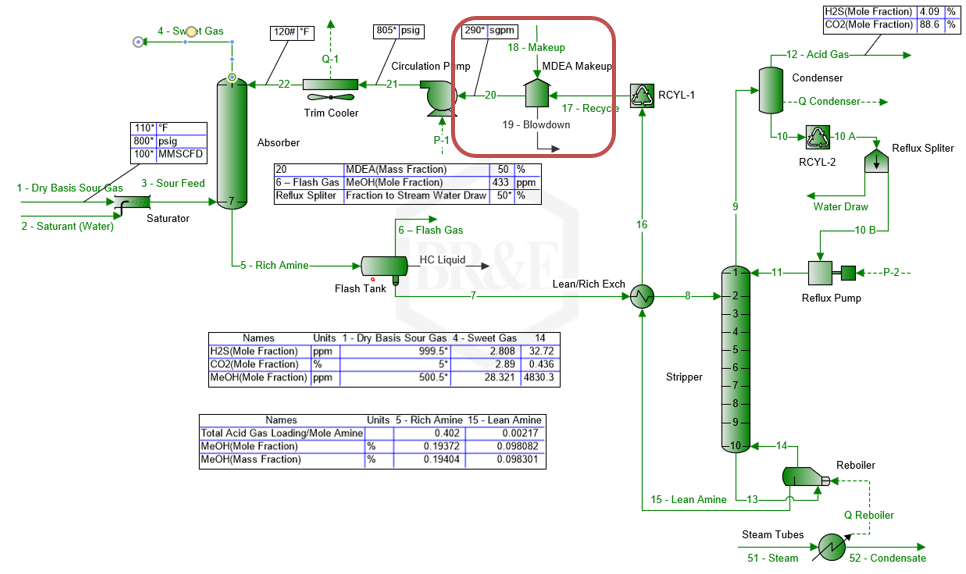

Determining Traces of Methanol in the Gas Sweetening Process - Updates

October 1, 2022

|

Tip of the Month

The July 2016 tip of the month (TOTM) considered the presence of methanol in the sour gas stream and determined the quantitative traces of methanol ending up in the sweet gas, flash gas and acid gas streams. To achieve this, the tip simulated a simplified MDEA gas sweetening unit by computer. That tip also studied the effect of feed sour gas temper...

View Article

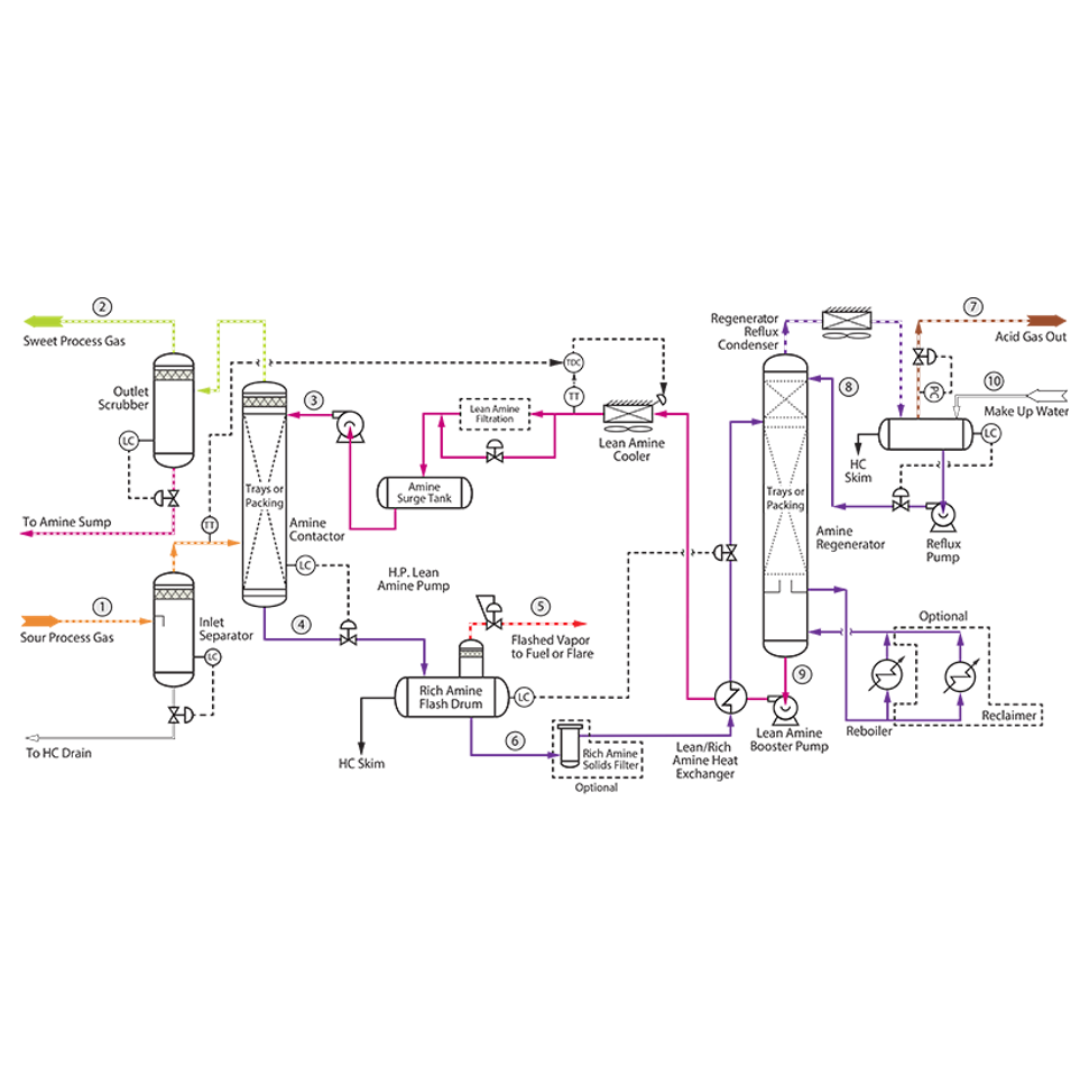

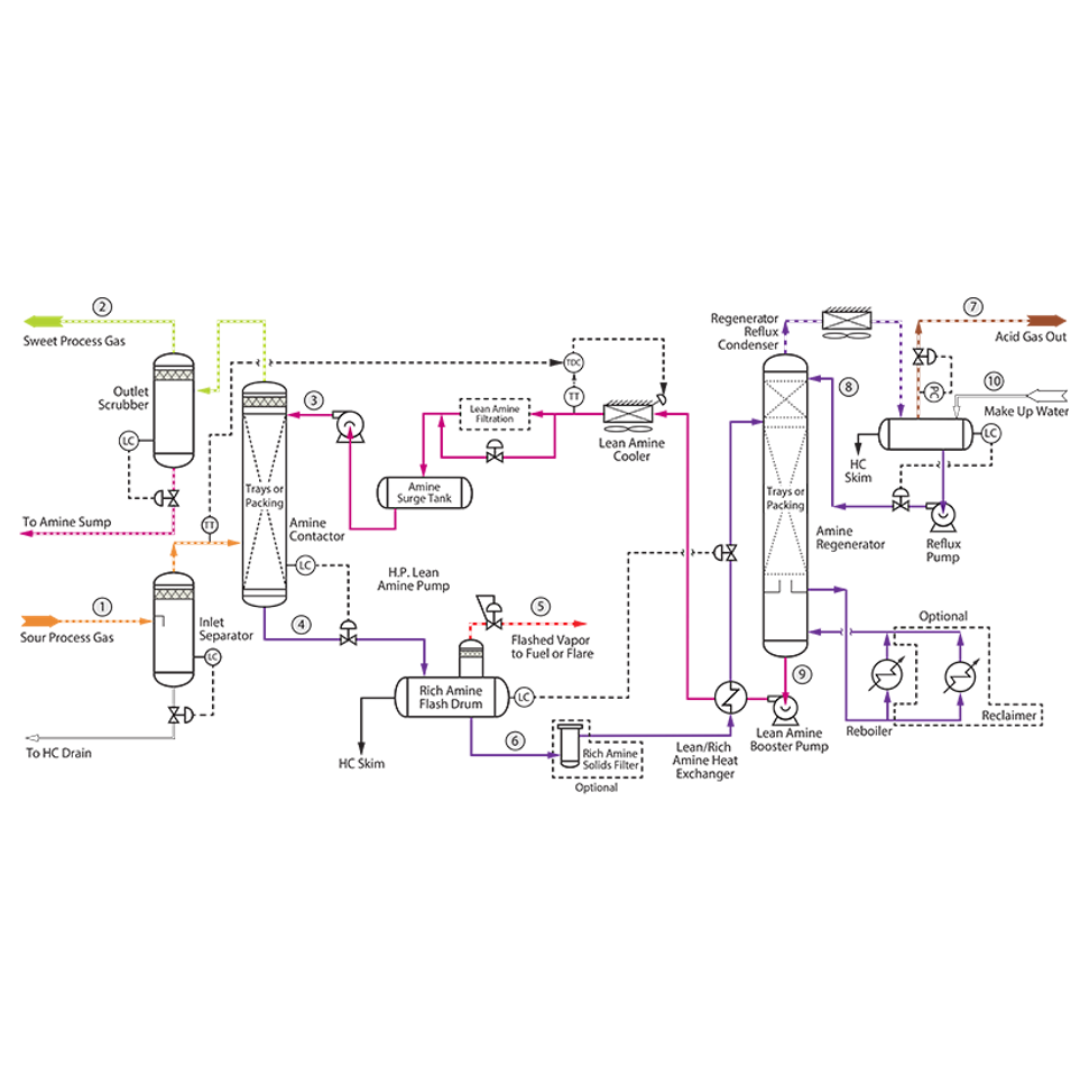

Part-2: Estimation of Solubilities of Benzene, Toluene and Ethylbenzene into Acid Gas Loaded Aqueous MDEA Solutions

August 3, 2022

|

Tip of the Month

Continuing July 2022 tip of the month, this tip demonstrates applications of the models developed based on the experimental VLE and VLLE data measurements presented in the Gas Processors Association (GPA) research report RR-242. The models will be used for estimation of solubilities of a mixture consisted of Benzene, Toluene, and Ethylbenzene in lo...

View Article

Gasoducto de Larga Distancia Nord Stream - Parte 3 Aplicación de las ecuaciones Básicas y AGA para aproximar el flujo máximo en un gasoducto de larga distancia

July 25, 2022

|

Tip of the Month

Introducción

En seguimiento de los dos últimos Previos del Mes (TOTM/PDM) sobre el gasoducto Nord Stream de larga distancia, el cual transmite el gas natural desde Rusia hasta Europa, este PDM resume la aplicación de varias correlaciones/ecuaciones disponibles para determinar la capacidad máxima de susodicha línea de larga distancia. Adicionalmen...

View Article

Nord Stream Long Distance Gas Pipeline – Part 3 Application of Basic and AGA equations for estimating maximum gas flow in a long‐distance pipeline

Following on the previous two tips of the month (TOTMs) on Nord Stream long distance pipeline for gas transmission from Russia to Europe, this TOTM discusses the application of various long distance gas transmission correlations/equations that are available to determine the maximum gas capacity of a long distance pipeline. In addition, calculations...

View Article

Parte 2 Corriente NORD STREAM – Varias vías paralelas hacia el éxito o fracaso?

Los Proyectos de la Corriente Nord Stream 1 & 2 son tremendos logros de la ingeniería. En un Previo del Mes anterior, hemos discutido los aspectos técnicos del Diagrama de Fase, y su fase densa correspondiente, la Hidráulica, Selección de Diámetro, Espesor de la chapa del oleoducto, perfil de la gradiente de presión, y capacidad de transmisión de...

View Article